American Magic AC37

American Magic – Mechatronics Engineer: Human Machine Interface & Simulation

At a Glance

Human Input Devices: Designed, prototyped, and built over 100 custom controllers (steering wheels, twist grips, flight/sail/cyclist controls) to meet evolving boat logic and rule changes.

Dynamic Control Logic: Transitioned from AC36’s basic “push-to-trim” inputs to AC37’s linked, sensor-driven dynamic control systems.

Crew Information Systems: Developed and tested multiple display systems, tactical layouts, cameras, AR concepts, and audio cues to maximize sailor performance.

Simulator Development: Co-developed a hardware-in-the-loop sailing simulator mirroring the race boat’s PLC, CAN bus, and controls for both training and design validation.

The Role

The Role

________________________________________________________________

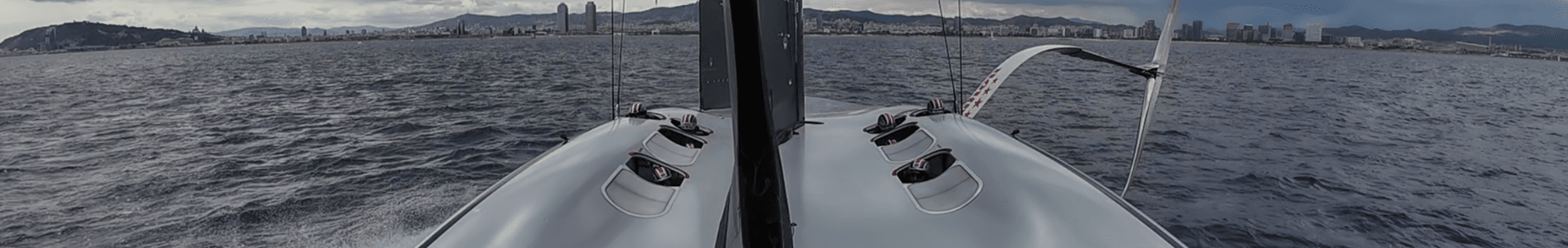

Engineering at the Edge: My Experience with American Magic in the 37th America’s Cup

Chasing the America’s Cup is like working at a fast-paced startup. You have a crystal-clear goal, an immovable deadline, and a small, highly focused team compressing months of development into days. Long hours, rapid iteration, and constant innovation are the norm.

During my time with American Magic, I worked at the intersection of mechanical, electrical, and software engineering — designing control systems, building cockpits, developing simulators, and ensuring our electro-mechanical systems could survive one of the harshest racing environments in the world.

From Push-to-Trim to Closed-Loop Control

When I joined the team, our AC36 yacht operated under strict “push-to-trim” rules — no feedback control, no preset target trims, no automation beyond holding a button to move the sail.

However, the AC37 protocol changes were a huge evolution. While still limited, they now allowed closed-loop position feedback control. This meant:

- Pressing a button could send a sail to a preset position.

- Different trim configurations could be loaded and recalled.

- Smart lookup tables could link control functions — for example, trimming sails as a function of foil cant or having the jib and main trim proportionally.

We still couldn’t use external environmental sensors or yacht state for fully automatic trimming — adjusting sails based on wind speed or boat speed was prohibited. But by designing clever sailor-driven inputs, we gave the boat partial awareness of its state and the surrounding conditions. This “dynamic control logic” became a foundation for much of my later work.

Rethinking the Cockpit

Traditional sailing has one driver, one trimmer, one flight controller, with crew crossing the boat during maneuvers. We decided this movement disrupted focus at the most critical race moments.

Our solution: keep sailors in place for the entire race. Two dedicated drivers stayed on their sides, and trimmers/flight controllers switched roles based on position. This allowed us to:

- Design cockpits around each sailor, like a Formula 1 car or fighter jet.

- Tailor ergonomics and control layouts to individual preferences.

- Integrate the new closed-loop control logic directly into the hardware.

Where old controllers were simple “press-to-trim,” the new ones would now feature position encoders, preset dials, twist grips, go-to-target buttons, and conditional logic.

Human Interface Devices & Rapid Prototyping

Because of the fast pace, even racing hardware was often 3D-printed with high-quality SLS or made from hand-molded/CNC-machined carbon fiber. New controllers went from concept to deployment in 1–2 weeks.

Highlights included:

- Formula 1-style steering wheels — custom grips molded to sailor hands, dozens of functions, displays, LEDs, encoders, paddle shifters.

- Specialized trim controllers — from Xbox-style grips to motorcycle twist throttles.

- Cyclor interfaces — enabling athletes producing 400+ watts of hydraulic power to also shift gears and input environmental data in near-real-time.

This was hands-on, iterative engineering — designing, testing, and refining under race-ready deadlines.

In parallel, I contributed to development of our custom hardware-in-the-loop simulator for testing aerodynamic models, vehicle dynamics, electronic systems, control logic, and cockpit ergonomics. This simulator was also to serve as a training platform for the sailors.

We converted two shipping containers into full-scale race pods:

- Identical controls, displays, and cockpits to the real boat

- Hardware-in-the-loop testing with the same PLC and yacht computers as the race boat, connected over CAN bus.

- AR/VR integration — sailors saw Barcelona’s harbor but also their actual physical controls.

The simulator served both as an engineering testbed and a full training environment for sailors — used for evening practice and race-day warm-ups.

Crew Information System & Cognitive Load Management

With crew pods positioned deep inside the boat for aerodynamic efficiency, direct visibility was minimal. We built a Crew Information System to give sailors full situational awareness:

- Panoramic displays — drivers could see all around the boat, flight controllers monitored foil arms, trimmers watched sail cameras.

- Dynamic yacht visualizations — 3D models matched boat pitch/roll in real-time.

- HUD smart glasses — presented 1–2 key data points without breaking focus from surrounding boats and tactics.

- Audio cues, overlaid maps, peripheral LEDs — inspired by fighter pilot research.

All of this complied with rules forbidding any manipulation of camera footage or data overlay on live video.

Reliability in Extreme Conditions

The AC75 is a wet, violent environment. Electronics were constantly exposed to:

- Saltwater immersion (sometimes minutes at a time during capsizes)

- High heat (baking in 90°F sun)

- Heavy mechanical shock and vibration

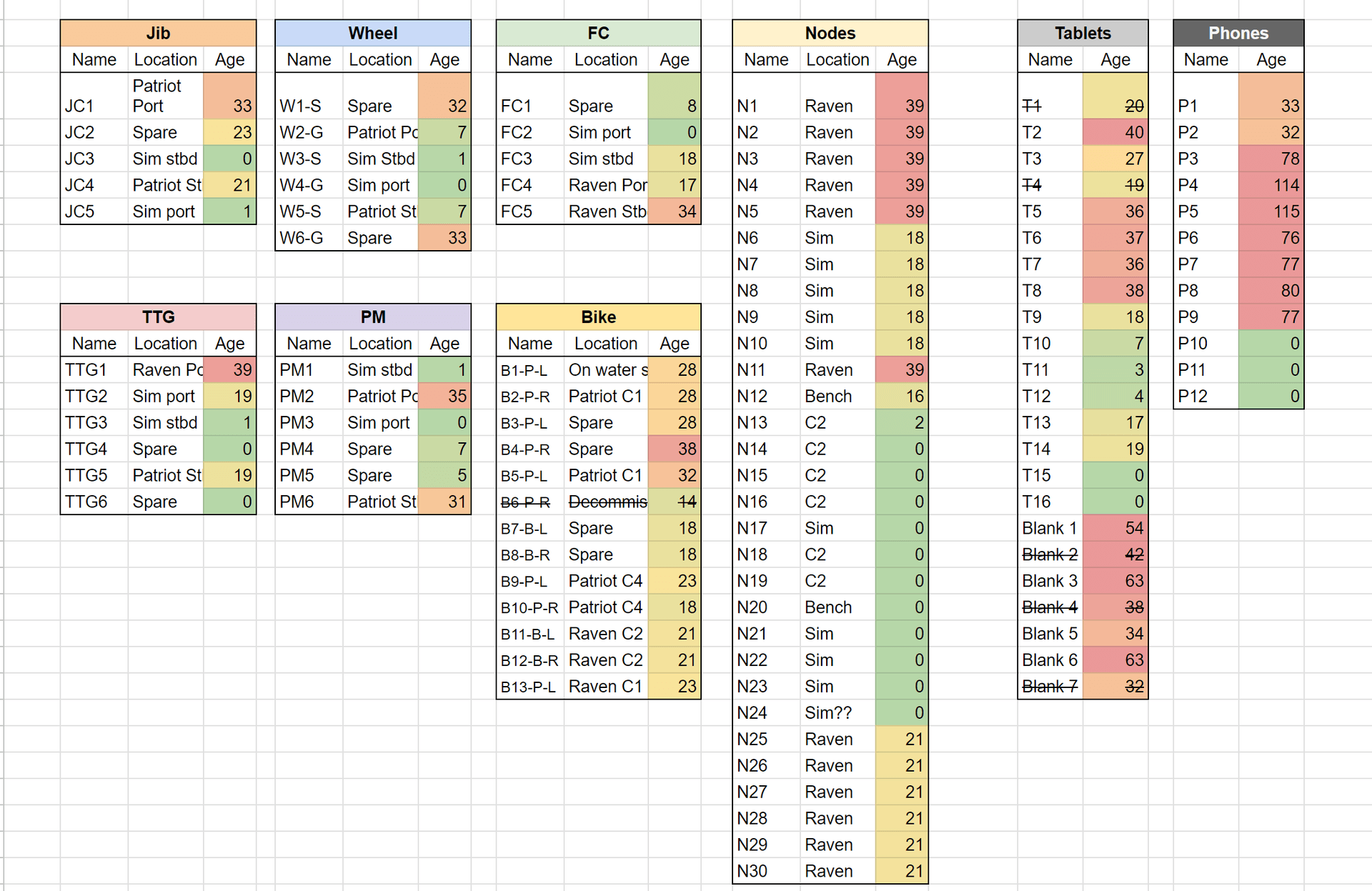

Full potting for waterproofing was too heavy, so I created a QR-coded lifecycle tracking system for all cockpit electronics:

- Every controller scanned before sailing.

- System logged total “sail days” and tracked the age of individual buttons, dials, and components.

- Incident logs recorded all failures and repairs.

The result was a color-coded health dashboard showing optimal controllers for race day. Data revealed the “sweet spot” for reliability: no controller should race before 6 sail days (break-in period) or after ~40 sail days (wear-out phase).

Outcome: Zero cockpit electronics failures during three months of racing.

Takeaways

Working on American Magic was the ultimate proving ground for rapid prototyping, systems design, hardware-in-the-loop simulation, and human-machine interface innovation — all while balancing strict rule compliance, ergonomic performance, and extreme environmental reliability.

It was fast-paced, high-pressure engineering — and exactly the kind of challenge I thrive on.

Read more about my time with this campaign:

WPI Journal Article: Liam Shanahan and The Race for the 'Auld Mug'