E-Foil Surfboard

Electric Hydrofoil Surfboard Build

At a Glance

- Built a custom electric hydrofoil surfboard from scratch

- Integrated high-voltage LiPo batteries, water-cooled ESC, and DC motor

- Designed “wet-run” motor housing with 3D-printed cooling system

- Created parametric 3D propeller for rapid testing

- Flush-mount electronics with LCDs + safety kill switch

__________________________________________________________________

Project Summary:

Around 2019, the remote-controlled electric hydrofoil surfboard was just starting to capture the attention of a few small companies and a handful of hobbyists. As both a surfing and engineering enthusiast, I was hooked on the idea—riding above the water on any lake or bay, without relying on wind or a boat for towing. It felt like the natural next step from my earlier obsession with building high-powered electric skateboards, only now the challenge was bigger: more power, higher voltages, streamlined hydrodynamics, and serious waterproofing, all hidden inside the thinnest board possible.

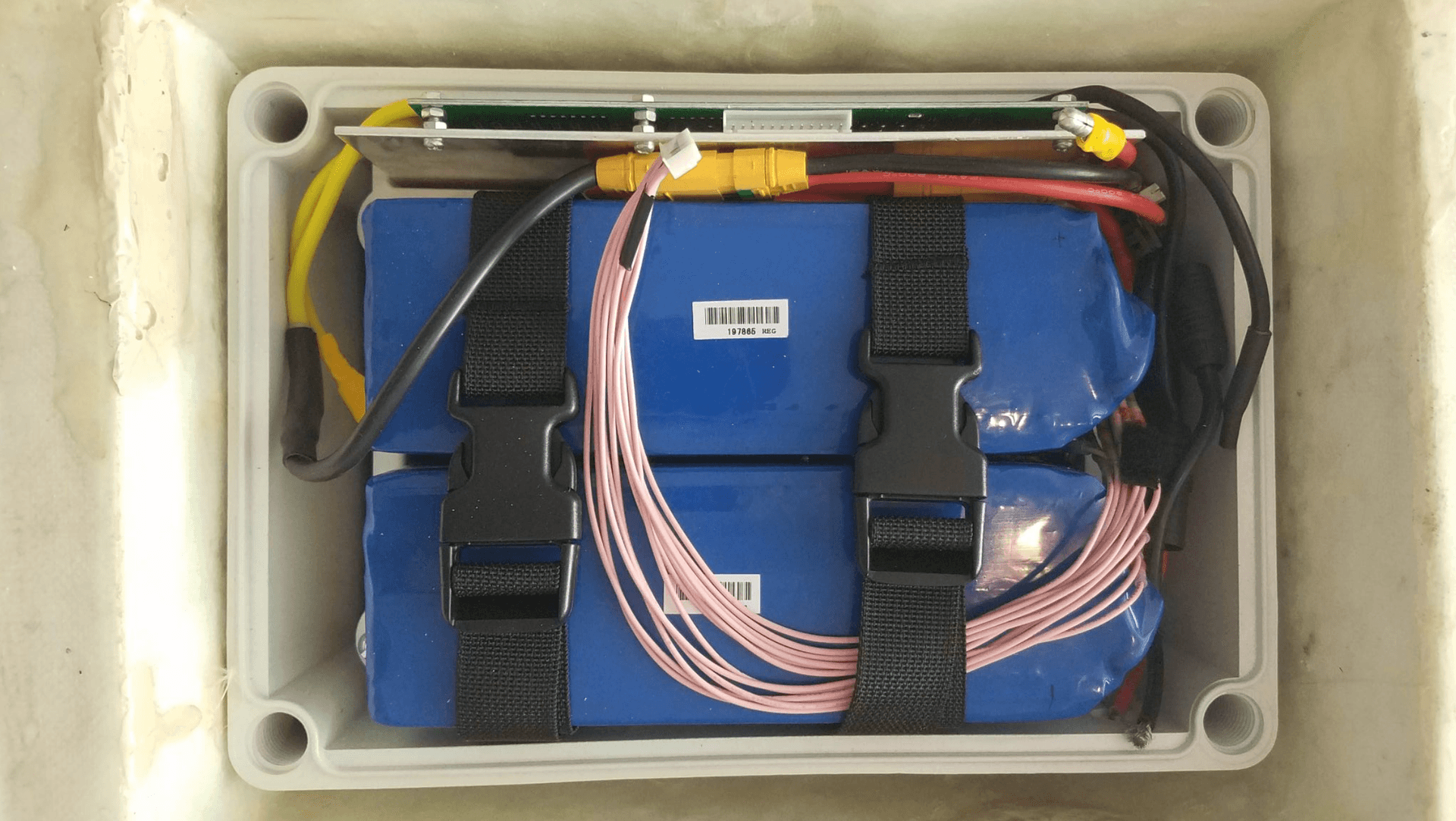

One big design challenge was runtime. My skateboards could cruise for six hours, but even the best foil boards topped out around 45 minutes. I started with two massive 10 Ah LiPo batteries, paired with a top-of-the-line water-cooled RC boat speed controller, a large DC motor, a battery management system, and the necessary fuses, thermometers, and kill switches.

For the board itself, luck struck—my neighbor was getting rid of a 12.5-foot fiberglass racing windsurf board. At 6.5 inches thick in its center section, it was just barely deep enough to conceal the battery box.

I cut it so the thickest part was at the rear for battery placement near the center of rotation, with the speed controller, pump, and other electronics forward of that. This layout gave me direct access to the foil mast for running both wiring and water-cooling lines to the motor.

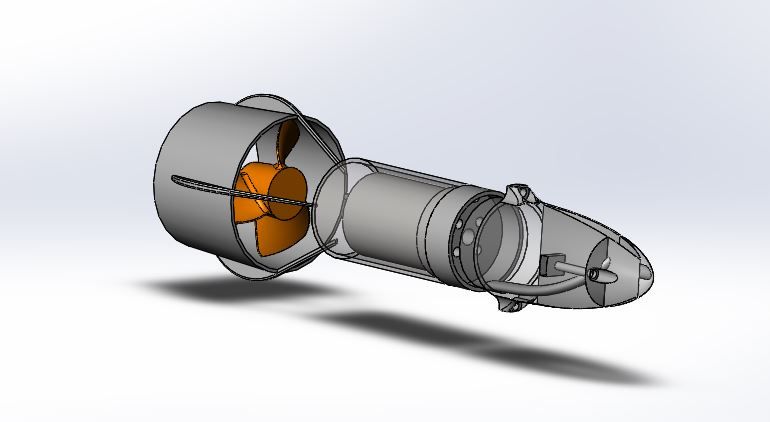

Rather than strapping Pelican cases to the deck like many hobbyists, I wanted a cleaner, more integrated look. I sourced two low-profile boxes that sat flush with the deck, covering them with foam grip tape. The motor was another interesting design challenge—fully sealed motors risk overheating, so I decided to run mine “wet.” I disassembled the outrunner, coated the coils and magnets in layers of conformal coating, and built a custom threaded aluminum housing with a 3D-printed nose cone and prop shroud. The nose cone had intake holes to channel water through the motor for active cooling before exiting at the tail.

Designing the propeller was a mix of math and experimentation. I created a parametric 3D model that let me quickly test blade counts, angles, and diameters, all inside a protective shroud. For the speed controller, I ran the three large-gauge motor phase wires down the mast along with a single vinyl tube to pump cooling water from the foil’s nose cone back up to the ESC’s sealed housing.

Safety was a priority. I mounted LCD displays to monitor battery percentage, power draw, and internal temperatures, and added a jet-ski-style kill switch and lanyard to instantly cut power if I fell—preventing the nightmare scenario of an unattended spinning prop.

The board worked, but it taught me hard lessons. Space inside the battery box was too tight, making maintenance and fuse changes difficult. More importantly, it was my first real dive into waterproofing, and despite meticulous sealing, water eventually found its way in through the many cutouts for buttons, screens, and ports.

In later years—through projects in far harsher marine environments—I learned that long-lasting waterproof design means minimizing cable penetrations, using only proven military-grade connectors, sealing critical electronics with RT-125 potting compound, and replacing physical switches with magnetic or hall-effect sensors wherever possible. This project was the start of that education—an ambitious, fun build that merged my love for surfing, engineering, and the challenge of making electronics survive in the ocean.