Stars & Stripes AC36

Stars & Stripes – Simulator Engineer

At a Glance

- Developed a custom simulator for the AC75 foiling monohull, enabling sailor training, control system testing, and CFD model integration.

- Integrated Gomboc physics engine to model aero-hydro interactions unique to foiling yachts.

- Collaborated with elite engineers and sailors to validate system architecture and control logic.

- Prototyped concepts for a 6-axis motion platform simulator inspired by Team New Zealand’s winning setup.

My Role

___________________________________________________________

In January 2019, I joined Stars & Stripes, a new challenger aiming for the 36th America’s Cup. This was a dream role—having followed the revolutionary foiling catamarans of AC34 and AC35 since high school, I now had the chance to help tackle an even more radical concept: the AC75 foiling monohull.

The AC75 was unlike anything before—75 feet long, monohull above the waterline, but supported by two giant actuating foil arms beneath. At the time, many questioned whether it was even possible to sail. Our small team of under ten people, led by match-racing world champion Taylor Canfield and marketing innovator Mike Buckley, set out to prove it could be done.

I was one of five engineers on the project, working alongside:

- Two founders of Vakaros (tactical sailing electronics) developing the onboard control systems.

- JB Braun, team CTO and Director of Desing at North Sails

- Bryan Baker, aerodynamics specialist with years of cup experienve

- Myself — responsible for building the team’s simulator for hardware-in-the-loop testing and sailor training.

Simulator Development

The simulator was the technical heart of my role and a cornerstone of our campaign’s engineering and training strategy. Its purpose was to:

- Allow sailors to begin training on a boat that didn’t yet exist.

- Give designers a way to test new CFD-based aero and hydro surfaces in a dynamic environment.

- Enable control engineers to refine the AC75’s complex onboard systems before hardware was built.

- Serve as a portable showcase to attract sponsors and donors.

Research & Architecture

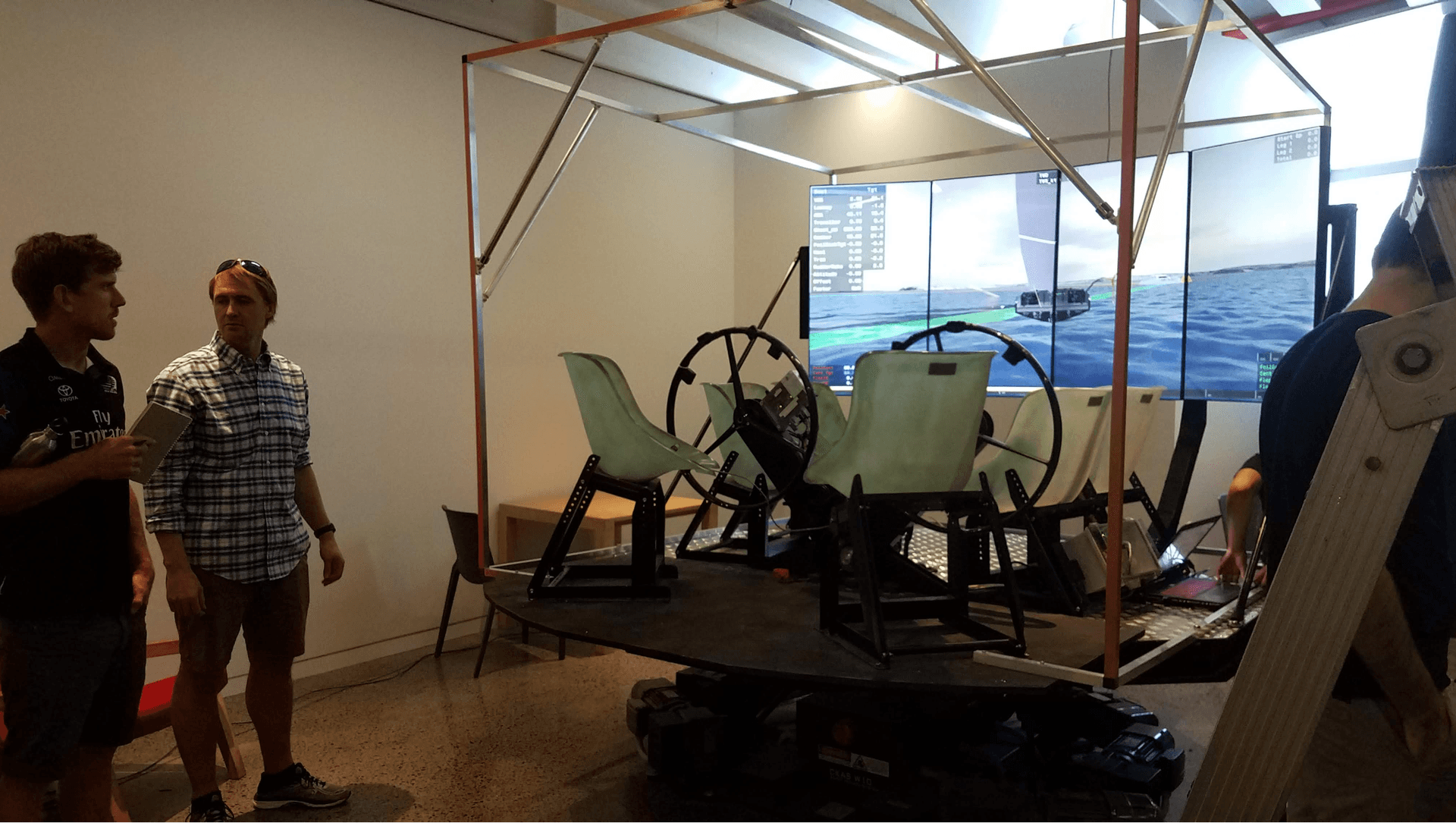

Early in development, the team secured the opportunity to purchase limited intellectual property from Emirates Team New Zealand, the Cup defenders. This included a visit to Auckland to study their systems firsthand.

We got to look under the hood of their motion platform simulator, originally developed for their AC35-winning foiling catamaran and now being adapted for the new AC75. At its core was Gomboc — a tool developed by team NZ but was now an off-the-shelf simulation software package. Gombocs greatest strength was a robust physics engine designed specifically for foiling yacht performance modeling. Gomboc excels at computing the combined aero-hydro forces across the air–water interface, which is essential for accurately simulating foiling yachts where both wind and water dynamics are tightly coupled.

Armed with my new understanding of Team NZs highly refined simulation system, I was able to begin work on our own. From this visit, I was able to reverse-engineer the simulator’s system

We decided to use the same Gomboc physics engine and create a small, standalone simulator to begin with. This would allow Bryan to input and test new aero and hydro CFD models and surfaces, the Vakaros boys to tweak and test system controls and dynamics, the sailors to train and understand the dynamics of sailing a boat that does not yet exist, and we would also be able to tranport this simulator to fundraising events around the country to allow people to "sail an AC75", and drum up excitement for our campaign.

Building the Stars & Stripes Simulator

Armed with that knowledge, I began building a standalone Stars & Stripes simulator using the same Gomboc engine. This initial version was designed to run without a motion platform, allowing us to get sailors, designers, and controls engineers working immediately.

Key features included:

- CFD model integration: Bryan Baker could rapidly load updated aero/hydro models from ongoing design work.

- Controls testing: The Vakaros engineers could implement and test their control logic for the foils, rudders, and sail trim systems in a realistic physics environment.

- Sailor training: Sailors could begin learning the handling characteristics and balance of an AC75 well before the boat was physically built.

- Portable engagement: The simulator could be transported to events and set up within minutes.

From Desktop Rig to Immersive Experience

The earliest build used a Logitech video-game steering wheel and pedal set hooked to a standard monitor. While functional, it was far from realistic. I redesigned the interface to include: - A custom-built carbon fiber steering wheel modeled after the actual AC75 helm, with integrated thumb controls for trimming, foils, and flight control.

- Foot controls for secondary inputs, matching real-world ergonomics.

- VR headset integration for full 360° situational awareness in the virtual cockpit.

- This upgrade transformed the simulator from a basic software testbed into a realistic training and engagement tool.

On the Road: Fundraising & Public Engagement

Still being an early stage team, fundraising was still a high priority at this stage. Therefore, Mike and Taylor were planning to throw a massive fundraising event at an estate in Bel Air, Los Angeles. Recognizing its value beyond engineering, We decided we wanted to showcase the simulator at the event to get people excited about the team.

I created a timed racecourse in the simulator and wrote a real-time leaderboard system. Guests could attempt to beat the team driver, Taylor Canfield’s lap time, with results instantly displayed on a secondary screen.

This approach gamified the experience, giving high-profile attendees a taste of the AC75 challenge while reinforcing the brand’s energy and innovation.

Planned Expansion

The next development phase was a full 6-axis motion platform simulator, mirroring Team New Zealand’s system. This would have enabled hardware in the loop testing, as well as allowing the entire crew to train together with realistic motion feedback.

Unfortunately, funding constraints ultimately cut this project short as our America's Cup dreams were dashed.

Takeaways

The simulator project demanded a fusion of systems engineering, physics-based modeling, custom hardware design, and user experience thinking. In less than a year, I took it from concept to an operational platform that served as both a serious engineering tool and a compelling marketing asset—all within the constraints of a small, fast-moving startup team.